SMTMATE ® & REFLOW OVEN

SMTMATE ® :

SMTMATE ®

REFLOW OVEN:

A Reflow oven is a machine used primarily for reflow soldering of surface mount electronics components to the printed circuit boards (PCB). The oven contains multiple zones, which can be individually controlled for temperature. Generally, there are several heating zones followed by one or more cooling zones. The PCB moves through the oven on a conveyor belt, and is therefore subjected to a controlled time-temperature profile.

REFLOW OVEN

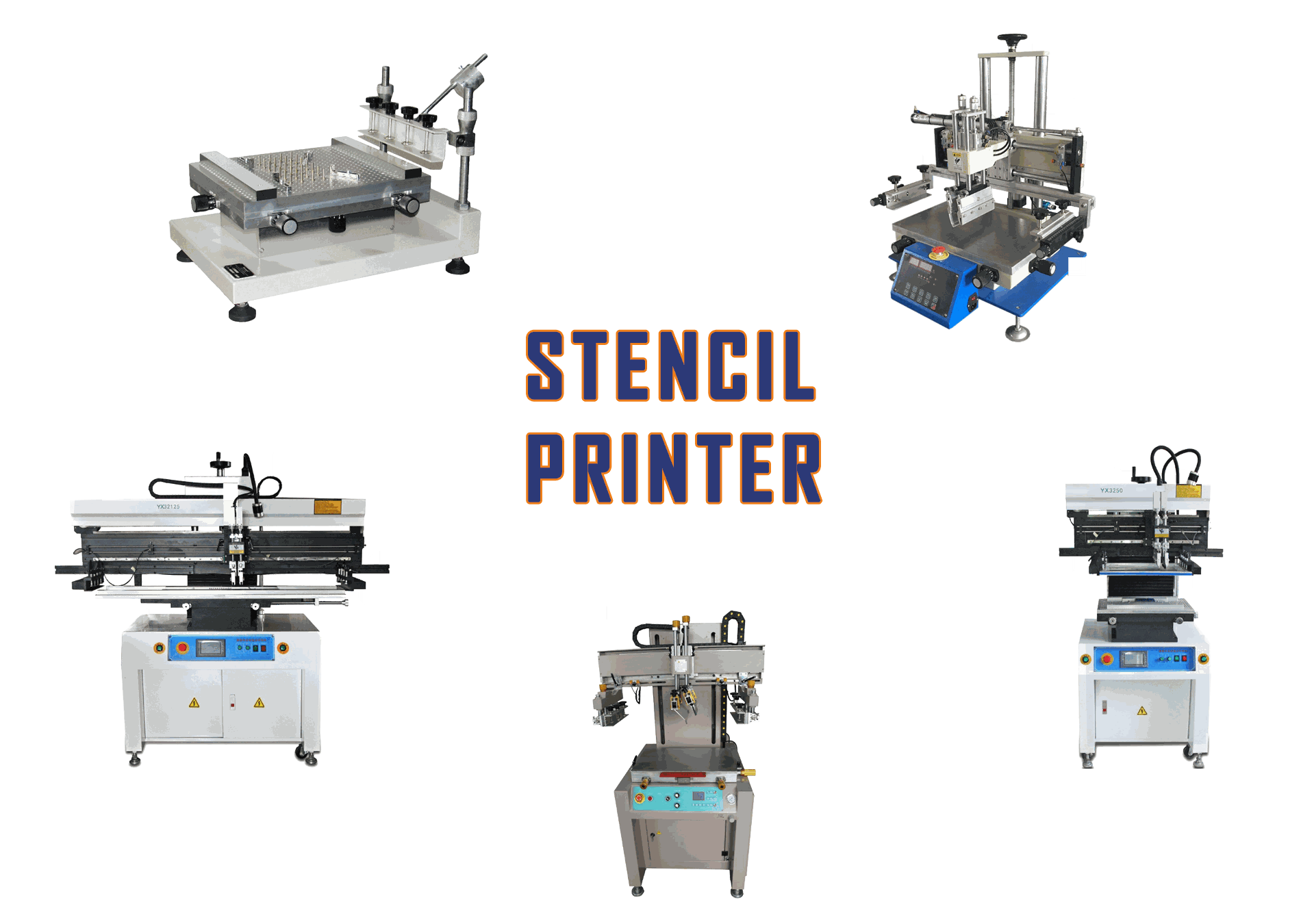

STENCIL PRINTER:

STENCIL PRINTER

SOLDER PASTE MIXER :